Wood Basics

A primer on how wood works

Early builders learned by trial and error which wood species to use and which wood from trees grown in certain locations and under certain conditions was stronger, more easily worked—or finer grained—than wood from other locations. White oak, for example, is tough, strong, and durable, which made it a prized choice for shipbuilding, bridges, barn timbers, fence posts, and flooring. Woods such as black walnut and cherry, on the other hand, were primarily valued as cabinet woods. Hickory was made into tough, resilient tool handles. Black locust was prized for barn timbers and trunnels (or “treenails”—the stout pegs used for joining timber frames). Modern research—much of it performed by the Forest Products Laboratory and through wood research programs at a handful of universities worldwide—has substantiated that location and growth conditions significantly affect wood properties and has given us the means to understand and predict wood performance.

Softwoods vs. Hardwoods

The differentiation of softwood and hardwood stems from the difference in two broad classes of trees defined by how they reproduce. The softwoods we use for building in the U.S. come mostly from conifers—the needle-leaved evergreen trees, such as pine, spruce, and fir. In botanical terms these trees are gymnosperms, which produce “naked” seeds in cones. Hardwoods come from angiosperms—flowering trees that produce seeds covered by a protective fruit of some sort (nuts, acorns, and samaras—aka "keys," such as those from maple trees—are all fruits). The hardwood trees used for building are typically broad-leafed, deciduous trees, such as maple, birch, and oak.

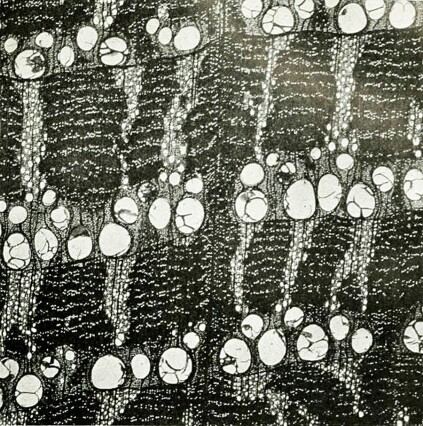

Softwoods and hardwoods have very different component cells. Softwoods have a simpler, basic structure with only two cell types and relatively little variation in structure within these cell types. Hardwoods have greater structural complexity with both a greater number of cell types and great variability within the cell types.

In each cube, the top view represents the transverse, or "end," surface; the left view, the radial, or "quartered," surface; and the right view, the tangential, or "plain sawn," surface.

On both samples: SU W: summerwood; SP W: springwood.

On the left, hardwood sample: V: vessel (or pore); TY: tyloses in a vessel; PAR: parenchyma cells (dark areas); WF: wood fibers; MR: small medullary ray; MR': large medullary ray.

On the right, softwood sample: TR: tracheids, which make up the bulk of the wood; MR: ordinary medullary rays; RD: resin ducts (voids between cells).

The single most identifiable difference between the two types of wood is that hardwoods have pores (or "vessel elements"). Individual pore cells are separated by perforated plates, and align end-to-end up the trunk. (In the image above, two pore cells are shown on the left side of the sample at left.) Water is conducted up the trunk of a hardwood tree by passing from pore cell to pore cell, driven through the permeable plates by a combination of forces:

- osmosis (the movement across a membrane from a high concentration of water to a low concentration) that pushes water up the trunk, beginning in the roots and continuing cell-by-cell, passing up through each pore cell;

- capillary action within the tubular pores;

- evaporation, which pulls water up the trunk as water evaporating from the leaves creates suction on each pore cell.

Fibers. The strength of hardwoods comes from fibers—spindle-shaped cells with relatively thick walls and small inner cavities that run vertically around the pores. Wood fiber cells are two to 10 times longer than individual pore cells. The thickness of the fiber cell walls, and the mass of fibers surrounding the pores, determines the wood’s density and strength. Low-density, low-strength hardwoods, such as cottonwood and basswood, have very thin-walled fibers; species with thick-walled fibers include hard maple, black locust, and ipe.

Rays. Fibers are not to be confused with rays. Medullary rays are chains of horizontal cells that extend in bands in a radial direction (perpendicular to the growth rings; in a transverse section, they appear as lines radiating from the center of the trunk). Ray cells in both hardwood and softwood trees serve to store food and distribute it horizontally across the trunk.

Hardwoods: White oak

Red oak

Hardwoods: Sugar maple (hard maple)

Yellow poplar

Instead of round pores, softwoods have long, rectangular tracheid cells that overlap vertically. These cells serve as both the wood structure, and a means to move water. The tracheids have circular "pits" at each end that connect to adjacent tracheids and are covered by a membrane.

Water flow up a softwood tree is driven by the three forces described above (osmosis, capillary action, and evaporation pressure), which move water across the pits from tracheid to tracheid in a zigzag fashion through the overlapping tracheids.

Softwoods: Douglas fir

Longleaf pine (southern yellow pine)

Softwoods: White pine

Redwood

Sap vs. resin. Many of the softwoods we use in building also produce resin, which is not the same as sap. All trees produce sap, which is mostly water with dissolved sugars and minerals that serves as the primary nutrient to sustain the tree’s growth. Resins, on the other hand, are secretions from specialized cells within the tree that provide a defense against infection and insects. The resin canals (which are actually voids between cells) are often quite distinct and visible by eye in pines, but they exist in most conifers. (In the photos above, resin canals are most prominent in the yellow and white pines, but there are a few in the Douglas fir sample, and much smaller but evident in the redwood sample.)

Sapwood vs. Heartwood

Sapwood is located next to the bark. It is the active part of a tree that conducts the water (sap) from the roots to the leaves. As a rule, the more vigorously growing trees have wider sapwood layers. Many second-growth trees of salable size consist mostly of sapwood.

Mussklprozz

Cells in the heartwood, the inner part of the tree, no longer conduct water up the trunk. As a tree grows, the cells harden and fill up with deposits of various materials that frequently give the wood a much darker color. In hardwoods, the pore cells grow tyloses , which appear in the pores like foam, that traps materials (gums and precipitates) and causes the cells to harden, usually making the heartwood stronger and more durable to weathering than sapwood.

Unless treated, all sapwood is susceptible to decay. In some woods, including redwood, western red cedar, and black locust, material deposited in the heartwood makes it heavier and more resistant to crushing than the sapwood.

Physical Properties of Wood

A spectrum of physical characteristics is available among the many species. Often more than one property is important. For example, when you are selecting an untreated species for a particular use, the wood’s texture, grain pattern, or color must be weighed against machinability (does the grain split out when nailed or the surface fuzz-up when planed?) and stability (will the wood shrink and warp more than other species for the given use conditions ?).

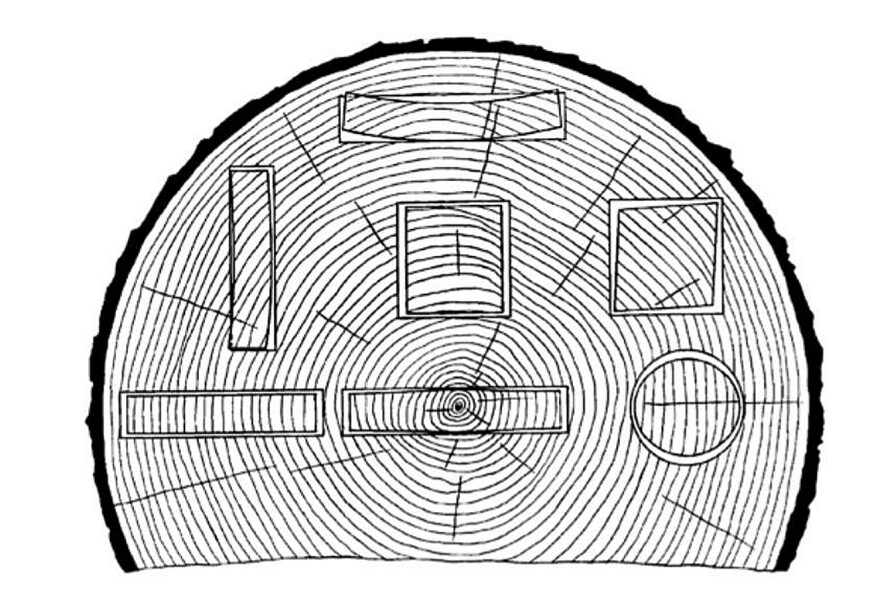

Plainsawn vs. quartersawn lumber. Lumber can be cut from a log in two distinct ways:

- When cut along a tangent to the annual rings, lumber is called "plainsawn" in hardwoods and “flat-grain" or “slash-grain” wood in softwoods.

- When cut radially (parallel or near parallel to a radius of the growth rings), lumber is called "quartersawn" or "vertical-grain" wood.

Quartersawn, or vertical-grain, lumber (A), cut radially (or near radially) to the rings, is sometimes preferred for its straightness, but plainsawn, or flat-grain, lumber (B) has more interesting grain patterns

Quartersawn lumber is usually not cut strictly parallel with the rays, and plainsawn boards are often far from being tangent to the rings. In commercial practice, lumber with rings at angles of 45° to 90° with the wide surface is called quartersawn, and lumber with rings at angles of 0° to 45° with the wide surface is called plainsawn.

Moisture content. Sapwood's moisture content is usually higher than heartwood's (though not in all species). Moisture can exist in wood as a liquid or vapor within cell cavities or as water bound chemically within cell walls. The moisture content at which cell walls are saturated (with “bound” water when no water exists in cell cavities) is called the “fiber-saturation point.” This averages about 30% moisture content for all species.

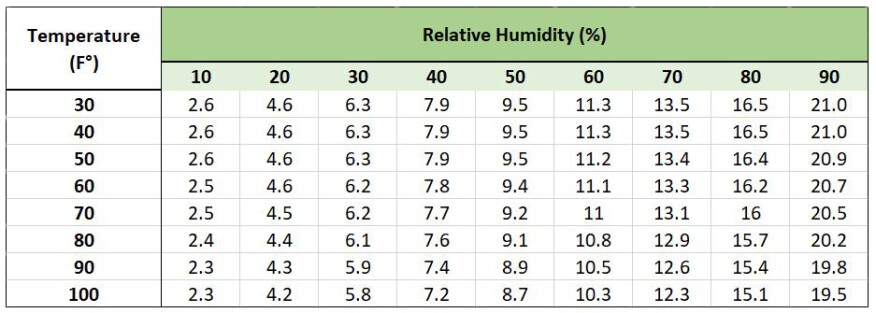

The moisture content of wood below the fiber-saturation point is a function of both the relative humidity and the temperature of the surrounding air. The relationship between equilibrium moisture content, relative humidity, and temperature is shown in Table 1 (below).

Table 1: The moisture content of wood changes as a function of the temperature and relative humidity. For example, if a space is 30°F and 80% relative humidity (for example, in an attic in winter), the wood there will slowly rise to 16.5% moisture content.

Wood in buildings is almost always undergoing at least slight changes in moisture content as the temperature and relative humidity of the surrounding air change. These changes usually are gradual. Short-term fluctuations tend to affect only the wood surface. Protective coatings such as varnish, lacquer, or paint will slow down the moisture content changes but will not stop them entirely. The general goal in seasoning and storing wood is to bring the wood near the moisture content that it will typically have in service. The protective finish then helps to slow down the changes and keep the moisture content within a more stable range over its service life.

Shrinkage. Wood is dimensionally stable above the fiber-saturation point. But below that point, it shrinks when losing moisture and swells when gaining moisture. This shrinking and swelling may result in warping, checking, splitting, or other performance problems.

Wood shrinks most in the direction of the annual growth rings (tangentially), about one-half as much across the rings (radially), and only slightly along the grain (longitudinally). The combined effects of radial and tangential shrinkage can distort the shape of wood pieces. The image above shows the distortion that is most likely in boards, depending on where they are cut from the tree.

Wood shrinkage is affected by a number of variables. In general, greater shrinkage is associated with greater density. The size and shape of a piece of wood may also affect shrinkage. So may the temperature and rate of drying for some species. Radial and tangential shrinkage for a few common species ate shown in Table 2 (below).

Table 2: Shrinkage values of selected woods along the rings (tangential) and across the rings (radial).

Longitudinal shrinkage. Longitudinal shrinkage (along the grain) is generally quite small—between 0.1% and 0.2% for most species of wood.

Certain abnormal types of wood, however, exhibit excessive longitudinal shrinkage. “Reaction wood,” whether it is compression wood in softwoods or tension wood in hardwoods, tends to shrink excessively along the grain.

Working Qualities of Wood

The ease of working wood with hand tools generally varies directly with the specific gravity (density) of the wood. The lower the density, the easier it is to cut the wood. A species that is easy to cut, however, does not necessarily develop a smooth surface when it is machined. Consequently, many U.S. hardwoods have been tested for machining properties. The results for a few species are given in Table 3 (below).

Table 3: Machining properties of selected hardwoods. The numbers represent the percentage of pieces with desirable characteristics in testing by the Forest Products Laboratory.

Three major factors other than density may affect the production of smooth surfaces during machining:

- Interlocked and variable grain: Interlocked grain is characteristic of tropical species. It can cause difficulty in planing quartered surfaces unless attention is paid to feed rate, cutting angles, and the sharpness of knives.

- Hard mineral deposits: Hard deposits, such as calcium carbonate and silica, can dull all cutting edges. This is worse when the wood is dried before milling.

- Reaction wood: Tension wood in hardwoods, especially, can cause fibrous and fuzzy surfaces and can pinch saws due to stress relief. The pinching may result in burning and dulling of the sawteeth.

Weathering

The color of wood is soon affected when exposed to weather. With continued exposure, all woods turn gray. This thin, gray layer is composed chiefly of partially degraded cellulose fibers and microorganisms. Further weathering causes fibers to be lost from the surface, but the process is so slow that only about one-quarter inch is lost in a century.

The chemical degradation of wood is affected greatly by the wavelength of light. The most severe effects are produced by ultraviolet light. As wetting and drying take place, most woods develop physical changes, such as checks or cracks. Low-density woods acquire fewer checks than do high-density woods. Vertical-grain boards check less than flat-grain boards.

Boards tend to warp (particularly cup) and pull out their fastenings. The greater the density and the greater the width in proportion to the thickness, the greater is the tendency to cup. Warping also is more pronounced in flat-grain boards than in vertical-grain boards. For best cup resistance, the width of a board should not exceed eight times its thickness.

Biological attack of a wood surface also contributes to color changes. When weathered wood has a dark gray and blotchy appearance, it is due to dark-colored fungal spores and mycelium on the wood surface. The silvery gray sheen often sought on weathered wood occurs most frequently where microorganism growth is inhibited by a hot, arid climate or salt air.

The contact of fasteners and other metallic products with the weathering wood surface is another source of often undesirable color.